Overview Knives for printing combs and independent production of steam knife

Knife beekeeper for printing combs (court) own hands.

Knife beekeeper for printing combs (court) own hands.

The invention of the steam knife was a real breakthrough in the field of beekeeping.

Earlier than any cell with his hands the print was not as effective and easy to use.

Beekeepers finally got rid of having to dip quickly holonuche blade in hot water.

Design features Beekeeping knives

The device consists of a cutter with wooden handle, heated blade is soldered using "coil" (steam line) Stainless Steel.

Hot steam flows through a flexible rubber tube from a special tank – steamer.

The second tube is designed for condensate, formed during use.

Steam beekeeper than factory production has the following options:

- The blade of the inside hidden channel. The width is typically less than 250 mm, and the thickness – 2.5 mm.

- heating element – boiler. Mandatory presence protects the valve.

- Hose-guide, submitting to the knife pairs.

- The tank capacity of up to 5 liters and weighing 1 kg.

Total weight of this type of maximum Beekeeping knives 1.5 kg.

The advantage of this instrument is, that he can long maintain the desired temperature, but the process requires constant boiling water in the tank paroobrazovatelya.

It is also necessary to control the liquid level.

Designed for printing combs than at home for small apiary.

How to use

Each printing process begins with a thorough verification of the rubber nozzle and tube steam.

It is important to ensure bandwidth every detail, because the blockage can lead to the injection of steam and pressure, perhaps, tank rupture.

Before proceeding to the cutting of honeycomb wax flip-off caps, need to wipe and dry all items knife.

To facilitate the work sharpened blade is recommended.

The method of operation of such a tool is very simple.

First, in a tank, appointed through this pipe, filled with water.

Further, begin to heat it to any device, whether gas or electric cooker.

Water vapor, formed by heating, comes to blades.

It adopts heat, which causes condensation, which is given through the other end of steam.

To collect the liquid at the edge of the tube should substitute capacity.

If given condensate easy to identify, or even remaining water paroutvoryuvachem.

When the blade rather nahrilosya, you can go to work.

steam, Despite its own temperature stability, provides uniform heating.

When finished collecting, excess fluid is drained, Beekeeping knives washed with warm water and wipe dry.

For long term storage is better to use clean and dry place.

Production at home

Simplicity of design instrument craftsmen to self-assembly.

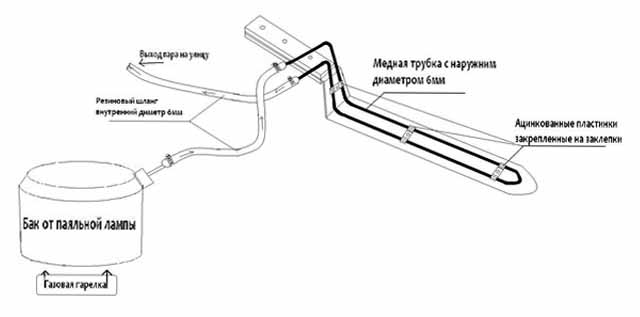

It will take a bit of material, to produce steam than to print cells with their hands:

- plate for blades, or preferably aluminum, or stainless steel;

- copper tube, external diameter 6 mm;

- rubber hoses, inner diameter 6 mm;

- metal container 4-7 liters, can be used as a tank.

The correctness of knife making with his hands confirmed compliance with certain requirements.

- Firstly, cutting plate should warm up evenly.

- Per-second, pen should lie comfortably in the hand.

- Thirdly, Blade is easily maneuverable and can zatochuvatysya.

Video: homemade beekeeping than heated.

Improved knives cells

In a large-scale beekeeping farm output much more, so they need more powerful equipment.

They used electric vibronozhi. Its equipment includes, in addition to the standard set, also electric.

As simple steam, vibronozh requires the same preparation and manipulation works on the same principle.

The difference is fortified wall electric motor, transmitting the knife reciprocates.

Naturally, the engine must be connected to 220V.

There is beekeeping elektronizh, blade which contains a heating element. The temperature can be adjusted in the range of 50 to 120 C, a heated blade in just a minute, which makes it possible to work in a high pace. His weight is no more 300 gram. Continuous operation is not limited, elektronizh makes it indispensable in large apiaries.

Heated cutters of all kinds significantly easier to work unsealing hundred.

Cons obvious – the need for heaters, control of the water level and the limited size of the tubes (up to 2 meters).

But, compared to conventional blades, Steam provides an even cut across the length of the frame with honeycombs and eliminate the ingress of water into honey.

In the steam knife, Unlike electric or vibrating, no need for power supply, so its always use remote apiaries.

The price of finished products is not high and fully pay all costs of purchase, but most beekeepers prefer to make their own knife, choosing the tube firmly, Tank bigger and better blades for metal.

PLEASE TELL COPPER STEAMER PRICE AND HOW CAN I PURCHASE IT.

You can try to buy it here. I bought for myself on Aliexpress

http://s.click.aliexpress.com/e/s9RNiw8